The following is based on my progression starting with a 'commercial' A3 frame bought 'online'.

Frame Adustments

I chose a Hampton Frames OSLOG A3 42 x 30 cm Natural Wood Effect Picture Poster Photo Frame Plexi (Non glass) OSLA3N

The frame-border is 20mm wide by 12mm deep, and the central rebate is a perfect fit for the A3 Printout: 297mm x 420mm.

The frame gives the appearance of being made from compressed sawdust, wrapped in paper, and some care is needed when cutting.

The backboard and glazing were retained by metal clips which can all be discarded...

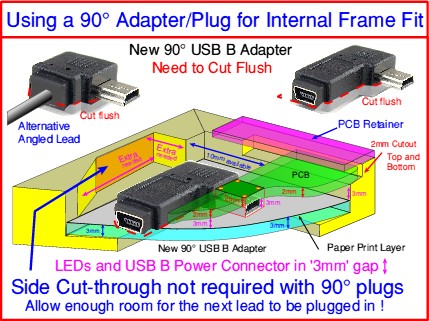

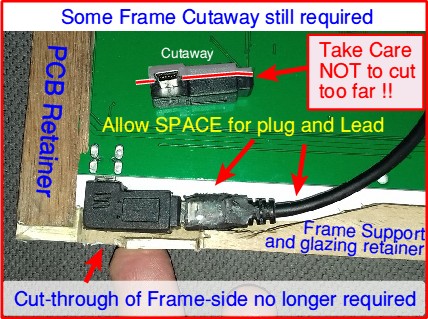

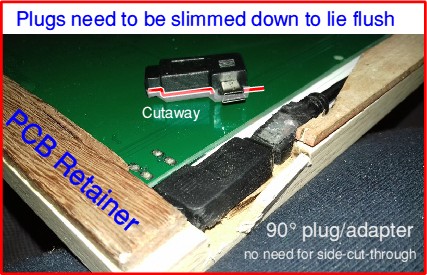

The PCB is about 4mm higher than the A3 297mm, and therefore a 2mm wide rebate has to be cut in the top and bottom frames.

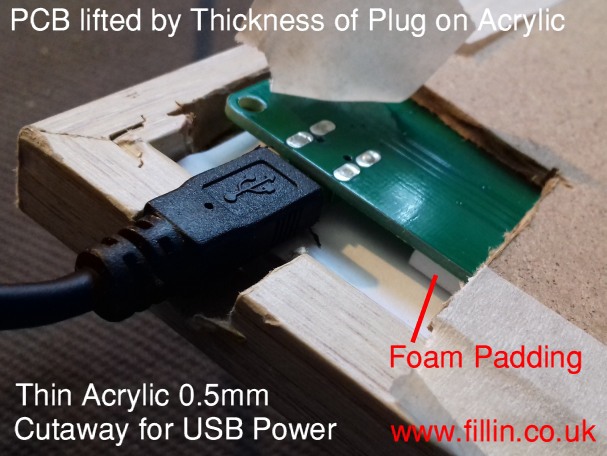

Working initially with the supplied 0.5mm Acrylic Sheet, the 2mm cutouts needed to be quite deep - leaving just 3.5mm of the frame

However, I soon discovered that it flexed too easily; separating from the Paper Print if the frame was angled forward.

I therefore ordered an A3 sheet of 3mm Acrylic [Acrylic being stiffer than Polycarbonate], which reduced the depth to be cut to about 2mm

This brought the inset PCB flush with the rear of the frame, so that a wooden strip glued to the bottom piece could act as a retainer.

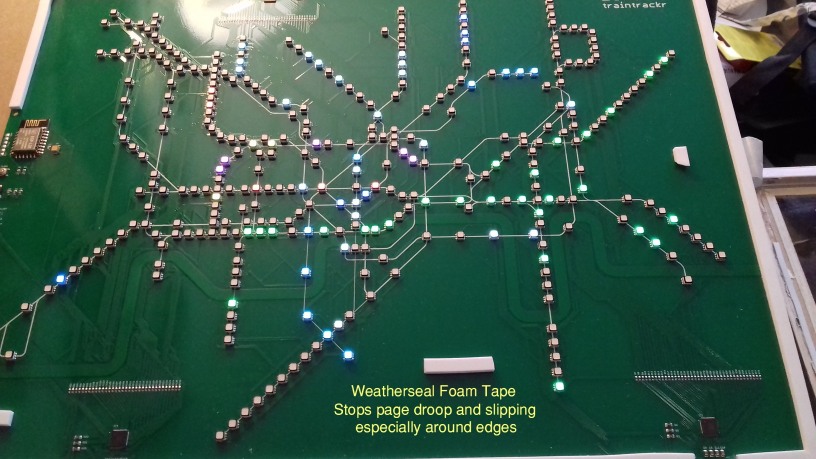

Having previously cut deeper, I used Weathersealing foam tape to pad-out the gap, helping hold the PCB in place laterally too:

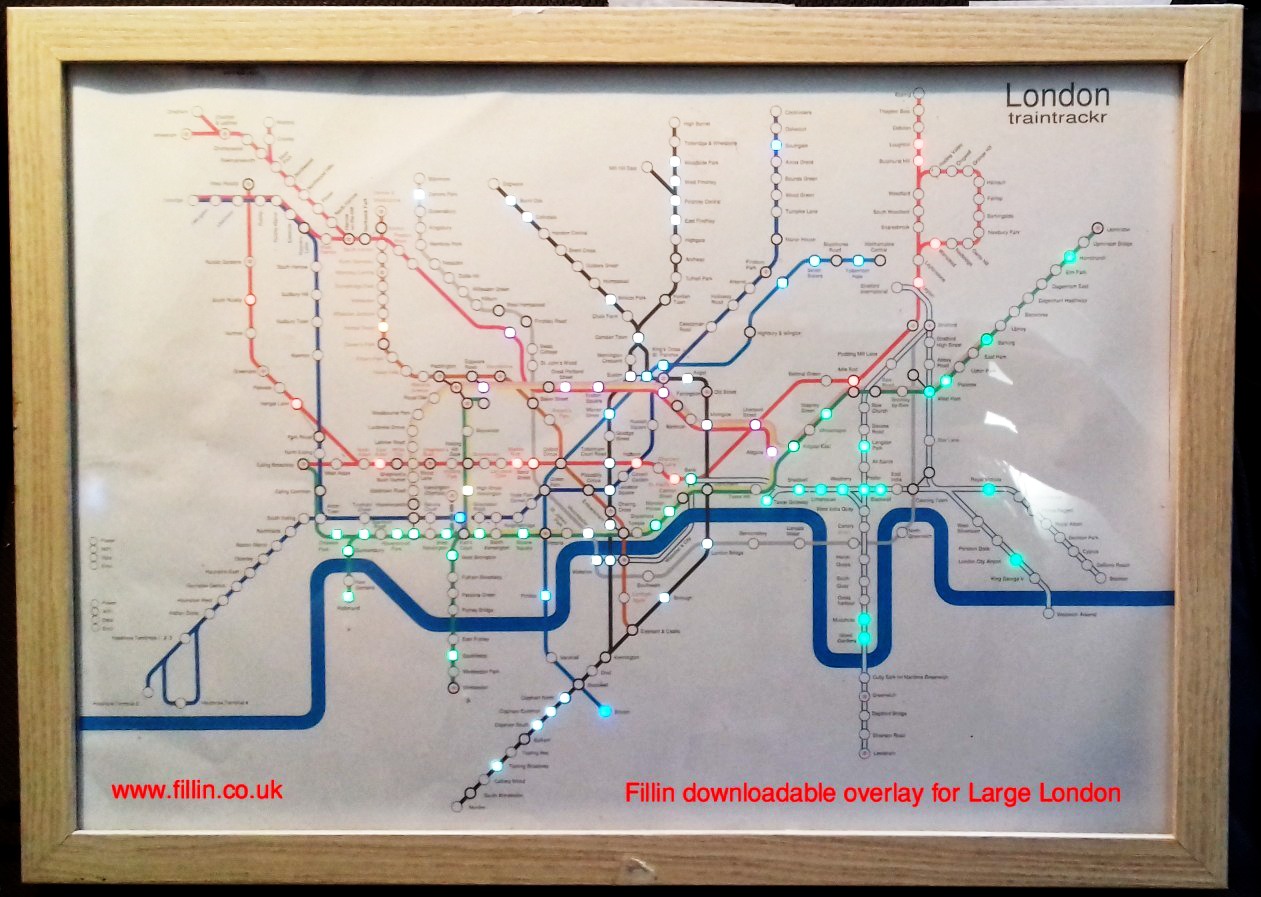

With the glazing and printout in place, the PCB was placed behind, and powered up to check the registration with the stations.

The 3mm weatherseal foam tape was also used around the PCB, and where there were no stations, to push the paper forward.

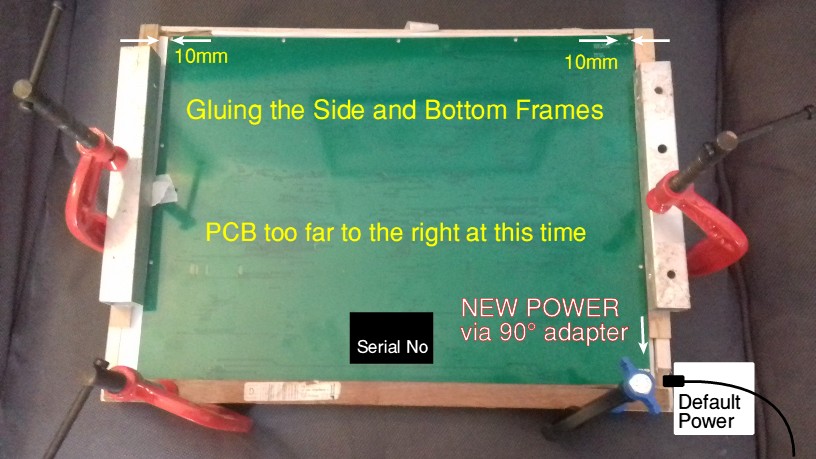

Horizontal Positioning of the PCB to Register with the Printout

The paper is simply located by the frame and the Weathersealing Foam tape so as to make changing it in the future easy.

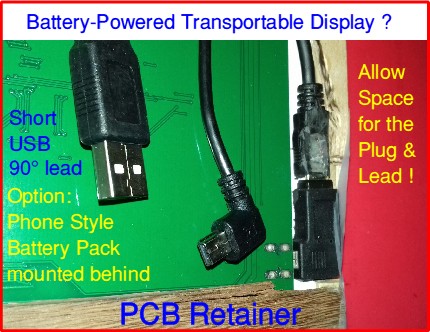

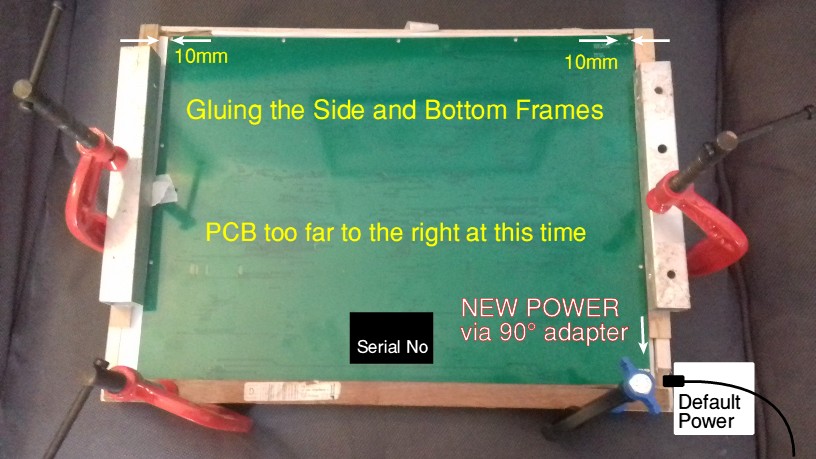

The wooden strip across the bottom retains the PCB securely whilst allowing it to be positioned horizontally.

There should be approximately 10mm gaps either side of the PCB which reveal the paper print.

Once all other construction had been completed, strips of Birch were glued to the upright side frames; overlapping inwards to retain the glazing,

and to provide a firm support for hanging eyelets as the original backboard will not be re-used.

Two short removable sections will be added across the top to hold the PCB firmly in place.

|